With the help of technologies such as the Internet of Things (IoT), artificial intelligence (AI) and big data, buildings can be operated more efficiently and sustainably. Digital processes can also be used to significantly accelerate energy-efficient retrofits in buildings as well as the construction of new buildings and homes. Fraunhofer ISE is conducting research on digital applications in the building industry and addressing the associated challenges and solutions for tradespeople and businesses. What opportunities does digitalization offer for a green transformation of the building sector? In view of the increasing relevance of the topic, Innovation 4E is launching a three-part interview series. For the second part, we spoke to Mona Mühlich about digital planning in construction processes. She has been working on her doctorate in the field of digitalization and automation of building design processes at Fraunhofer ISE since September 2023.

You are a PhD student researching the topic of serial building refurbishment in the Fraunhofer flagship project Bau-DNS. Can you tell us about this project?

The Fraunhofer-Gesellschaft’s flagship projects are developed in cooperation with various subsidiary institutes and serve to stimulate industrial cooperation with the aim of bringing innovative ideas to the market quickly. As its name suggests, the Bau-DNS lighthouse project is aimed at the digital, sustainable and systemic production of energy-efficient building refurbishments. We want to make the refurbishment process significantly more cost saving, efficient and productive. Currently the rate of refurbishment is very low at 1%. Our aim is to bring it up to 2%, which is the value required to achieve the climate targets. Fraunhofer ISE is primarily concerned with digitalization processes within the planning process and with approaches to systemic construction, in our case with the development of flexibly installable building-integrated photovoltaic (BIPV) modules for façades. My focus is on the topic of construction planning processes using the example of prefabricated façade systems for serial refurbishment.

Example building façade: What are the advantages of digital processes in serial refurbishment?

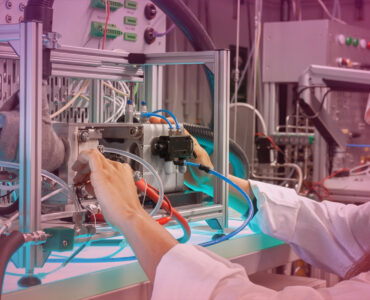

Façades are particularly complex building elements in the construction planning process, as they involve expertise from several trades at once. At Fraunhofer ISE, we have been conducting intensive research into BIPV façades and other active building elements for years. When installing such façades, it is necessary to interlink the prefabrication, mechanical fastening and electrical engineering processes. Much is happening in the field of prefabrication. There are companies that can supply a completely prefabricated wall structure, including the windows and pipes. We, on the other hand, are trying to go between on-site production and complete solutions by introducing a modular construction method. For example, we develop partial elements that can be combined freely and take on multiple functions like thermal insulation and energy generation. A digital workflow is a prerequisite for the serial refurbishment with functional prefabricated modules. Existing digital models form the basis for the planning. With the end-to-end digitalization of the planning processes, plans for prefabrication and the installation of the modules are directly created.

What role does systemic manufacturing play in this context? What makes it so sustainable?

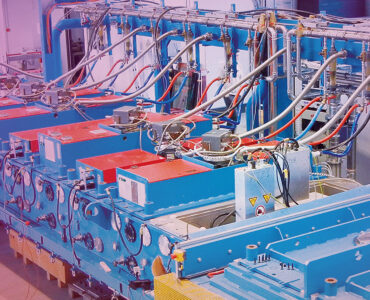

In future, planners should be able to choose active and passive building elements from a sortiment of modular systems. This will enable them to respond individually to the given conditions of a building and its surroundings. Elements that do not generate energy would be integrated into areas of the façade that are heavily shaded and those with energy-generating functions would of course be integrated on façade surfaces exposed to lots of sun. This type of flexible and modular system would simplify the handling and installation processes, since no large equipment, such as cranes or scaffolding, would be needed to erect the façade. The modules could be produced automatically and according to demand by creating standardized digital construction kits. Research into the necessary industrial design is already being carried out as part of Bau-DNS project. For example, our colleagues at the Fraunhofer IFF are working on automated factory lines. The modular design also facilitates the maintenance work that must be carried out regularly once installed, due to the electrical elements in the modules. In addition, systemically designed modules are advantageous since they can be easily dismantled and also replaced individually. In our research we address the important goals of resource efficiency and recyclability in order to improve the overall ecological balance.

How can digitalization contribute to increasing the rate of refurbishment?

Our aim is to develop digital tools and methods that streamline the construction planning process and thus reduce the overall time required to realize a construction project. Principally we are focusing on the first four service phases of the construction and planning process in accordance with the Fee Ordinance for Architects and Engineers (HOAI). The optimization of these four processes would already save a great deal of time. We are currently evaluating the current status quo of digitalization within the construction industry in the planning phase. In the planning stages mentioned above, digital applications focus primarily on drawing software and on Building Information Modeling (BIM), which has, in fact, been in use since the 1980s for managing building data and the associated work processes. We are looking at the strengths and weaknesses of the BIM method in order to supplement or develop any missing tools.

Apart from saving time, what benefits do innovative BIM tools offer architects and planners?

In particular, we want to support smaller architectural firms and small and medium-sized businesses in the trade sector. Unlike large planning offices that often have their own BIM experts, small and medium enterprises (SME) do not have the capacity to implement digital processes in their day-to-day work. Particularly in Germany, construction processes are based on division of labor due to the high proportion of SMEs involved. On top of that, the coordination processes are becoming increasingly complex. At Frauhofer ISE we offer digital methods that facilitate the involvement and exchange of all players in the construction process and help speed it up. Our fundamental research aim is to reduce complexity, increase productivity and minimize costs due to errors in order to positively improve productivity for the entire construction industry while increasing sustainability at the same time.

To what extent could planning offices benefit from the use of AI in the future?

There are already some BIM software manufacturers that integrate AI methods into their applications, and we at Fraunhofer ISE are currently analyzing this market ourselves. In many areas, smart systems or AI need to be “trained” with questions and expert knowledge before they can become operational or used effectively. In general, accessible chatbots are not suitable for this, as they draw on a knowledge basis that is much too broad and non-specialized, as expert knowledge in the internet is often not available for free. We are investigating potential applications in which AI systems can react and provide competent support for the construction process. For example, transferring geometric or semantic data between the different players in the design process is usually somewhat problematic. AI programs can help to make it easier for planners to find their way through the sometimes overwhelming amounts of data. Up to now, AI solutions are available for specific planning areas, however, a comprehensive digital tool does not exist.

What innovations can be expected for visualization software?

My colleagues in the “PV-Antiblend” project are currently working on a plug-in for the 3D modelling software Rhino used by many planning offices, which should make it possible to visualize the glare risks of PV systems. This should also give architects and planners access to the reflection data of PV modules so that they can identify suitable glare reduction technologies for a building already in the planning phase. With this plug-in, it shall be possible to depict building façades very realistically. The European cooperation project MASS-IPV initiated by Fraunhofer ISE also aims to advance the digital visualization of façade designs – not least in order to overcome aesthetic reservations about multifunctional façades. With our research into modular façade systems, we primarily want to provide planning offices with design flexibility. They should be able to choose between building elements that openly display their ecological advantages through the visibility of PV constructions and others where the energy-supplying function takes a back seat to the appearance, e.g. by directly replacing building elements with PV elements.

BIPV is considered an important building block for a green building revolution. Can digital approaches support the expansion of this technology?

In order to drive forward energy-efficient refurbishment, we need to upgrade the building envelope. With BIPV, built surfaces in urban environments can be used to generate green electricity. Digital tools are decisive for assessing the energy potential of building envelopes in the planning process and making optimal use of the available area with as little planning effort as possible. Fraunhofer ISE has many years of expertise in this area. We offer solar potential analyses that take into account the given building architecture and its surroundings. Using simulation tools, we calculate complex building geometries and consider (partial) shading in order to provide optimal solutions for the given circumstances, e.g. by adapting the PV module interconnections.

Where do you get your practical knowledge from? How do you exchange ideas with industry?

Some colleagues in our team have practical planning experience. I myself studied architecture. Our projects with industry and research partners serve as an important learning resource. Both sides always learn something new. Another method of exchange is through the round tables that we organize to bring together experts and companies working in the construction industry. We involve not only players from Germany but also from other countries, such as France and Switzerland, where the processes are defined somewhat differently. Since many working steps in the construction industry are based on experience, the necessary documentation required to identify problems and their causes, is often missing. At ISE, we are continually on the lookout for experienced discussion and project partners so that we can gain more insight into the processes and remain up to date with the industry. Inquiries are very welcome! We are also part of the Fraunhofer Building Innovation Alliance, a network of various Fraunhofer Institutes that offers a market interface for integral system solutions in the construction industry. The Fraunhofer Alliance is organized in such a way that we can process customer inquiries in a targeted manner.

Add comment