In simple terms, how do PVT collectors work?

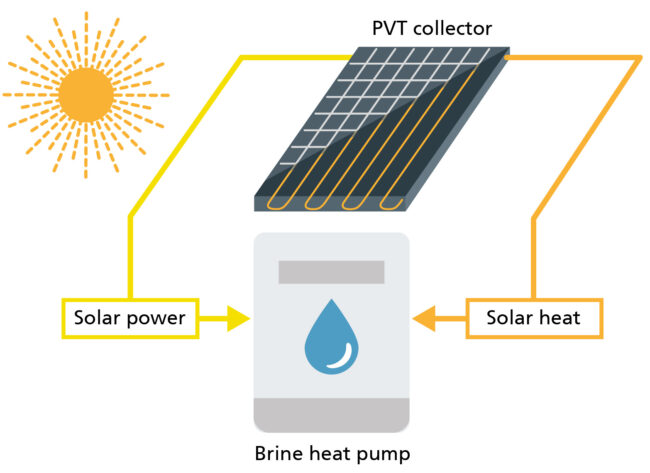

PVT collectors convert solar energy into both electricity and useful heat, and therefore are also known as hybrid collectors. The PV module part of the PVT collector generates electricity, which when used for the system technology, reduces its dependence on the power grid. For the heat generation, a heat exchanger, filled with a so-called “heat transfer fluid”, is mounted directly behind the PV modules. The heat transfer fluid transports the solar heat from the roof to the consumer. A heat pump, for example, can use the thermal energy as a heat source. In this case, the PVT collectors function as the heart of a highly efficient heat pump-based heating system for single and multi-family homes in both new and existing buildings. Even though PV and solar thermal technologies are not new in themselves, we at Fraunhofer ISE regard PVT as an independent technology in the field of renewable energy, as it has applications in areas that were previously not covered by either conventional PV or solar thermal systems.

What types of PVT system are available? How is the market developing?

There are roughly three types of PVT systems: uncovered, covered and concentrating. The choice of product depends on the required operating temperatures and the specific requirements of the thermal application.

Uncovered PVT systems currently dominate the German market with a share of around 95 percent. Overall, the market for PVT systems is developing positively. In 2022, it grew by 126% in Germany, reaching a total installed collector area of 150,000 square meters. Although it is still a niche technology, interest is growing rapidly, also among photovoltaic module manufacturers. In the “IntegraTE” project, we are working together with relevant manufacturers from the industry to support the market development of PVT as an energy-efficient technology (see box below). Some manufacturers are already ramping up their capacities.

For whom is a PVT system worthwhile?

A PVT system is currently appealing to people who are planning to modernize their heating system with a heat pump. Particularly when the ground is not an option as a heat source, PVT collectors are a good alternative. Another advantage is that no outside air unit is required thanks to PVT collectors. It is important to bear in mind, however, that the investment costs of a PVT system are higher than for a PV or a purely solar thermal system. On the other hand, a PVT heating system is highly efficient. While PV modules alone can convert up to 20 % of the incoming solar radiation into electricity, the total efficiency of PVT collectors (electricity + heat) is around 70 %. With PV modules, most of the solar radiation is lost in the form of heat, while PVT collectors can use this thermal energy for purposes such as heating.

Is PVT also interesting for industrial plants or municipalities?

At the systemic level, PVT systems that either supply heat energy at higher temperatures for direct use or are directly integrated into heating networks at different temperature levels is conceivable, which opens up the technology to corresponding fields of application. In our new “integraTE-XL” project, we are focusing specifically on larger systems, i.e., the refurbishment of apartment blocks or the energy retrofit of commercial properties, in which we plan to use demonstrator systems that we develop together with system manufacturers. The demonstrator developments will be accompanied by simulation, energy monitoring and effective market communication. We believe that properties with limited roof space can also benefit from PVT technology. Costs can be reduced through scaling effects in production and standardization in the planning and implementation processes. This is also where the project and the companies involved come in.

What are the advantages of a PVT system combined with a heat pump?

A PVT system in combination with a heat pump has the advantage that solar radiation and air are used as heat sources. Other advantages are that excess heat energy can be used in summer to regenerate geothermal probes and the available roof space is used in a highly effective way. In the best case, both ground excavation and outside air units become unnecessary, thus saving money and investment costs. Disadvantages, on the other hand, are the lack of installers, as the technology is not yet widespread. The planning costs, as mentioned previously, can also be a disadvantage due to the more complex application.

How can efficiency be increased?

The field test for PVT systems in combination with a heat pump in single-family homes shows that the system combination works well for building renovations as well as for new buildings. The practice also showed that the system efficiency can be increased by optimizing the singular components and their interaction as well as by implementing intelligent system controls.

Here at the institute, we are continuously working on increasing the efficiency and reducing costs. Our aim is to pool the expertise from the different research areas of photovoltaics, solar thermal energy and systems engineering which are available at the institute in order to advance the technology further. From our colleagues working in the field of photovoltaic modules, for example, research findings from material development, or also the shingle technology and alternative encapsulation processes for PV modules, are really interesting for us. For PVT collectors, the lamination, or EVA, films that connect and protect the individual layers of PV modules are often the limiting factor, as they remain stable only up to a certain temperature. Our research and development on these special issues benefits many manufacturers of PVT collectors, who do not have the facilities and expertise to study these themselves. When not only standard materials and processes are used but also new options are considered, it opens up more degrees of freedom for PVT applications. Of course, this immediately puts the cost pressure back to a different starting level.

What other research do you do at the institute?

Utilizing the heat from the PVT in a smart way is ultimately the central question on the system level. To make products market-ready, they must be thought through from the beginning to the end. We must ask and answer questions like: Where does the heat go in summer? Where does the electricity come from in winter? In what form is the energy to be stored? At what cost? As electric storage or heat storage? How can the investment and operation costs be allocated to the two different conversion paths, e.g., What does one kilowatt-hour of electricity and one kilowatt-hour of heat from a PVT system cost?

There really are many important questions in this research field that are worth answering. Incidentally, there are also a lot of very interesting products in other European countries. We have many international partners and through our international research activities, association work, conference participations, standardization work and joint work within the framework of the International Energy Agency IEA, we are driving this great technology forward within a broad network of experts.

How much space does a PVT system need?

The area required for a PVT system depends on various factors such as the building heating demand as well as the energy output of the system. An exact calculation of the required collector area can be calculated using planning programs. For a monovalent heat pump PVT system, in which the PVT is the only heat source for the heat pump, a rough estimate for the collector area is around four square meters of collector area per kilowatt peak rated output (4 m²/kWp) of the heat pump. However, it is important to note that this depends on the design of the chosen product and should only be considered as a rough rule of thumb. If the customer opts for PVT, the collectors can be installed over the entire available roof area to avoid wasting space and achieve a homogeneous appearance.

Speaking of appearance: Can color accents be added to PVT collectors in a similar way to PV modules?

Yes, PVT collectors can also be individually colored to enhance the appearance of buildings or even entire districts. Together with partners from industry, Fraunhofer ISE has developed the patented MorphoColor® technology, which gives collectors an intense and homogeneous color while maintaining over 93 % of their efficiency at the same time.

integraTE – Promoting PVT collectors and heat pumps in the building sector

The "integraTE" initiative for the dissemination of PVT solar collectors and heat pumps in the building sector aims to increase awareness of this efficient technology. The aim of the initiative is to determine the status quo of currently available and implemented PVT heat pump systems (PVT-HP systems) and to close gaps in the market boundary conditions. To this end, system simulations are set up and made available online free of charge, and selected systems are measured and evaluated on the basis of field data with regard to their energy efficiency, CO2 savings and heat generation costs. The project consortium will use this data to create information material for various user groups such as planners, craftsmen and women and housing associations. integraTE is funded by the Federal Ministry of Economics and Climate Protection (BMWK).

Add comment