With the help of technologies such as the Internet of Things (IoT), artificial intelligence (AI) and big data, buildings can be operated more efficiently and sustainably. Digital processes can also be used to significantly accelerate energy-efficient retrofits in buildings as well as the construction of new buildings and homes. Fraunhofer ISE is conducting research on digital applications in the building industry and addressing the associated challenges and solutions for tradespeople and businesses. What opportunities does digitalization offer for a green transformation of the building sector? For the third part of our Innovation4E blog series, Moritz Ihlenburg presents Fraunhofer ISE’s technological solutions for HVAC companies. The scientist with a focus on data analysis has been working since 2019 on various projects on the topic of energy and process efficiency through digitalization.

Digital applications are in demand for craft businesses. How does the ISE address this growing market?

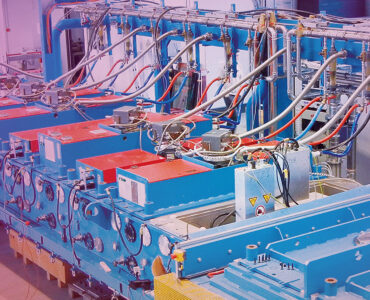

We are working on various projects to develop digital tools and workflows to accelerate or simplify work processes in the HVAC trade. This encompasses all procedures from inventory recording and planning through offer creation to the installation and operation management of building technology systems. In our project “DiBesAnSHK“, together with partners from the software industry and craft businesses, we have developed, for example, a workflow for the inventory recording of heating systems. This aims to speed up the rather time-consuming manual process of inventory recording for craftsmen by transferring the inventory data directly into a digital model of the system.

How does the digital inventory recording of heating systems work?

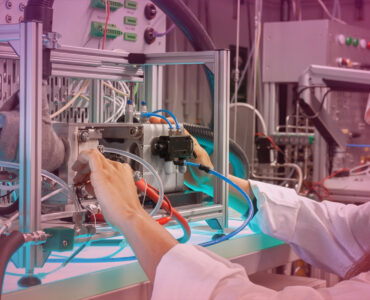

Based on recordings made with a mobile device, such as a smartphone or tablet, the heating components are automatically recognized using Lidar information. A digital model of the heating system is then created from this data. This model can be enriched with additional information, such as product data, to create a comprehensive digital representation of the system and enable optimized workflows in system operation, such as maintenance.

Is artificial intelligence also used in this process?

Yes, we use modern machine learning algorithms from the field of computer vision for object recognition of the system components. Cooperating craft enterprises provided us with recordings of heating systems in advance, generated with software from one of our partners. These images were labeled based on a classification system we developed and then used as training data. Building on this, we were able to train a model that recognizes common component classes in a heating cellar, including tanks, boilers, or heat pumps.

How reliable is object recognition? Is further development needed here?

As already mentioned, the object recognition we use is based on machine learning methods. However, we are also exploring how the use of generative AI, such as Large Language Models (LLMs) like ChatGPT, can support these processes. In the image processing procedures we apply to heating systems, product labels that contain information about components from various manufacturers are also recognized. These include product names or identifier, as well as technical parameters. We use LLMs to determine the most suitable component class from a predefined list based on this information. Our studies have shown that integrating LLMs can achieve higher accuracy in classifying heating components with product labels. This is particularly true for components that are difficult to distinguish using object recognition methods but can be clearly identified on a label.

The project partners come from the HVAC, IT and software industry. Where is there an acute need for a solution?

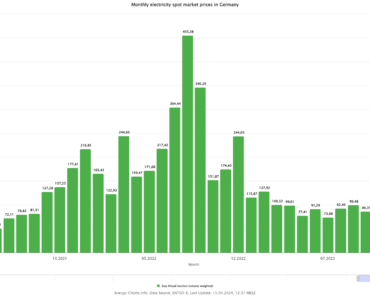

In “WESPE“, a project involving the German Sanitation, Heating and Air Conditioning Association (ZVSHK), the Innung Berlin, industry representatives, and researchers from the Fraunhofer IBP, the goal is to accelerate the expansion of heat pumps. A key factor here is reducing the longer installation times compared to gas boilers. As part of the project, we lead the work package “Development of digital workflows” and have developed the “Heat Pump PlanAR-App,” a digital application designed to speed up the planning processes of heat pump system hydraulics. For IT companies, this research is interesting to position themselves with innovative products in the growing market of craft software. Craft enterprises, in turn, can work more efficiently and counteract the problem of a shortage of skilled workers.

What is the innovation of the Heat Pump PlanAR app?

Our app supports installers through augmented reality and digital 3D recordings by providing automated suggestions for connection and piping planning. The heating room is scanned, and zones where components cannot be placed are defined. Then, either schematics of common heat pump installations or individual components from a list—based on VDI 3805 datasets—can be imported and freely placed in a 3D room or 2D planning view. The connections of the components are created according to their connection information and automatically positioned in the room using an optimization algorithm. In the future, we also want to consider additional normative aspects, such as component placement requirements, and provide interfaces to widely used craft software. Currently, the app is still in a prototypical development stage.

How important is collaboration with the heating industry?

Since we integrate not only abstract components but also market-available products into our app, we use product information provided by manufacturers. Ideally, these are standardized VDI 3805-compliant product data descriptions of components that the app’s algorithms can utilize. For the automatic piping of components, information about their respective connections must be stored, for example. Because providing information is such an important topic, we have also analyzed data availability and quality in “WESPE” and regularly exchange ideas with various manufacturers. High data quality is the basis for efficient digital workflows and tools.

The energy transition depends significantly on qualified specialists. Does the ISE also cooperate with training companies?

We are definitely concerned with how vocational training and further education in the HVAC trade will look in the future. Compared to installing a gas boiler, installing a heat pump requires specific expertise, particularly in handling refrigerants or constructing foundations, but also deeper knowledge in electrical engineering. Additionally, the increasing networking of various smart home components requires a thorough understanding of control technology and digital topics. In this regard, the curricula of vocational training lag behind actual needs. In the “LearnSHK” project, we are investigating, in collaboration with the Handwerkskammer Freiburg and the University of Education Freiburg, how training and further education in the HVAC sector need to evolve. We outline future technological challenges and identify the necessary skills that trainees should acquire. The goal is for the topics developed in our research projects to be quickly implemented in training.

With the prototype of the Heat Pump PlanAR-App, a first milestone has been reached. What are the next steps?

From March 17 to 21, 2025, we will be presenting the app together with the German Sanitation, Heating and Air Conditioning Association (ZVSHK) at this year’s ISH. Trade fair visitors will have the opportunity to try out the app themselves at a special exhibition stand. Subsequently, we aim to further develop the app in collaboration with interested software service providers and achieve licensing. Interested parties are warmly invited to contact us!

Add comment