In the wake of the changeover to renewables in the energy and transport sectors, storage systems are a key technology. They will play a major role in the energy transformation, from balancing the fluctuating feed-in from renewables through to making a 100 % renewable energy supply possible. Also in the transport sector, storage is crucial for electric mobility. For all these storage applications, power electronics is decisive for providing power conditioning and the interface for increasingly intelligent and complex energy and transport systems.

Energy storage systems are categorized into five different classes according to their technology: mechanical, chemical, electrochemical, electric and thermal. To store and later deliver the energy as electricity, an electrical interconnection is required for regulating the energy flow into and out of the storage. Depending on the type and dimension of the storage system, these electrical connections range from large power units (generators and motors), for example, in pumped storage plants, through to the small electric converters (power packs) for cell phones or laptops.

Electrochemical storage based on the lithium-ion technology is presently the most well-known and widely used type of electrical storage in daily life. It is available today in many sizes with capacities ranging from several watt-hours (cell phones, laptops, etc.) or kilowatt-hours (electric mobility, photovoltaic self-consumption systems) up to several megawatt-hours (stationary large storage systems). The DC output voltage of this technology depends on the present battery state-of-charge and can range from several to one thousand volts DC, depending on the given cell and module connections. In the future, this range will continue to increase, reaching a projected maximum, for the moment, of fifteen hundred volts DC.

The DC output voltage of the battery reaches its maximum when fully charged and sinks towards its minimum voltage threshold when discharging. Since the given application needs a constant voltage supply during operation as a rule, the output voltage of the storage medium must be converted to match the load voltage. In order to do this with as little loss as possible while controlling the power flow at the same time, power converters are mandatory.

In connecting storage systems, the efficiency of the power electronics can have a large effect on the performance and costs. For mobile applications, other criteria such as the power-to-weight ratio and power density are also play a role. This is illustrated with the following two examples.

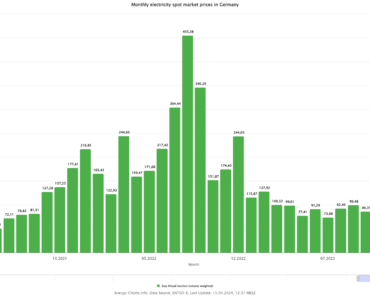

Consider, for example, a typical 5 kWp photovoltaic system with 5kWh home storage. For a 5 kWh battery capacity, the nominal power of the power electronics would be typically 3 kW. According to the most data specification sheets, the system efficiency is above 95 %, whereas these figures refer to the optimal operating point of the system. In fact, systems more often than not operate at partial load. For example, in a home the typical base load (e.g. refrigerator, freezer and standby loads) is less than 200 watts for more than half of a year. The efficiency of good battery systems with 3 kW nominal power drops significantly below 70 % when operating at 200W. For lower quality systems the efficiency can sink even below 50 %, which means that actually 400 W must be taken from the storage in order to cover the 200 W base load. For a period of six months at an electricity price of 0.30 €/kWh, the conversion losses of electricity amount to a total of 260 euros. Besides the purely economic losses, valuable PV electricity is also wasted. Already today, efficient, optimized operating modes contribute to minimizing the losses during partial load operation through the use of intelligent algorithms.

This example can also be applied to electric mobility applications: Higher conversion losses occurring between the battery and the drive train lead to a correspondingly shorter driving ranges. (Up to now, this effect has played a subordinate role for the consumer compared to the capacity losses due to the outdoor temperatures.) For electric mobility, the power density (watt/liter) and the power-to-weight ratio (watt/kilogram) are decisive for the power electronic performance.

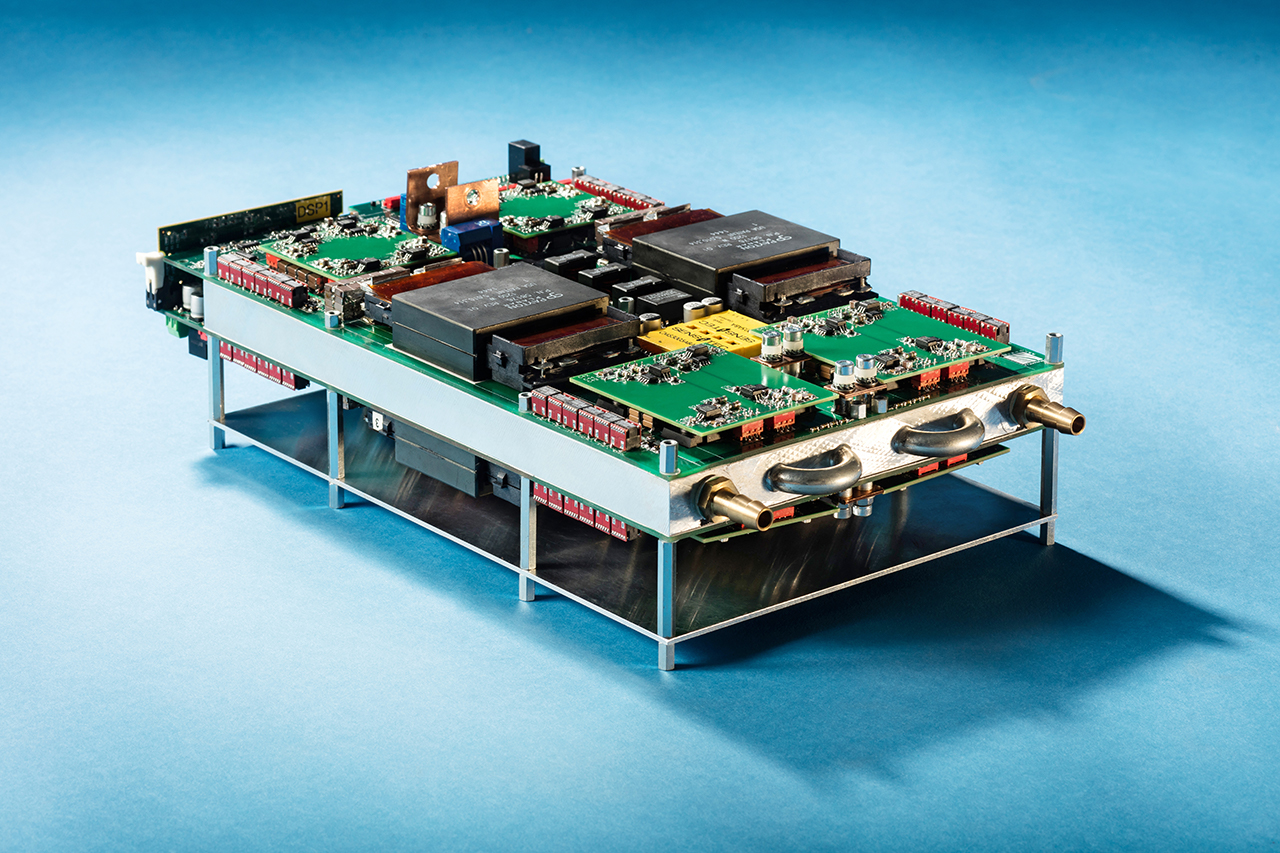

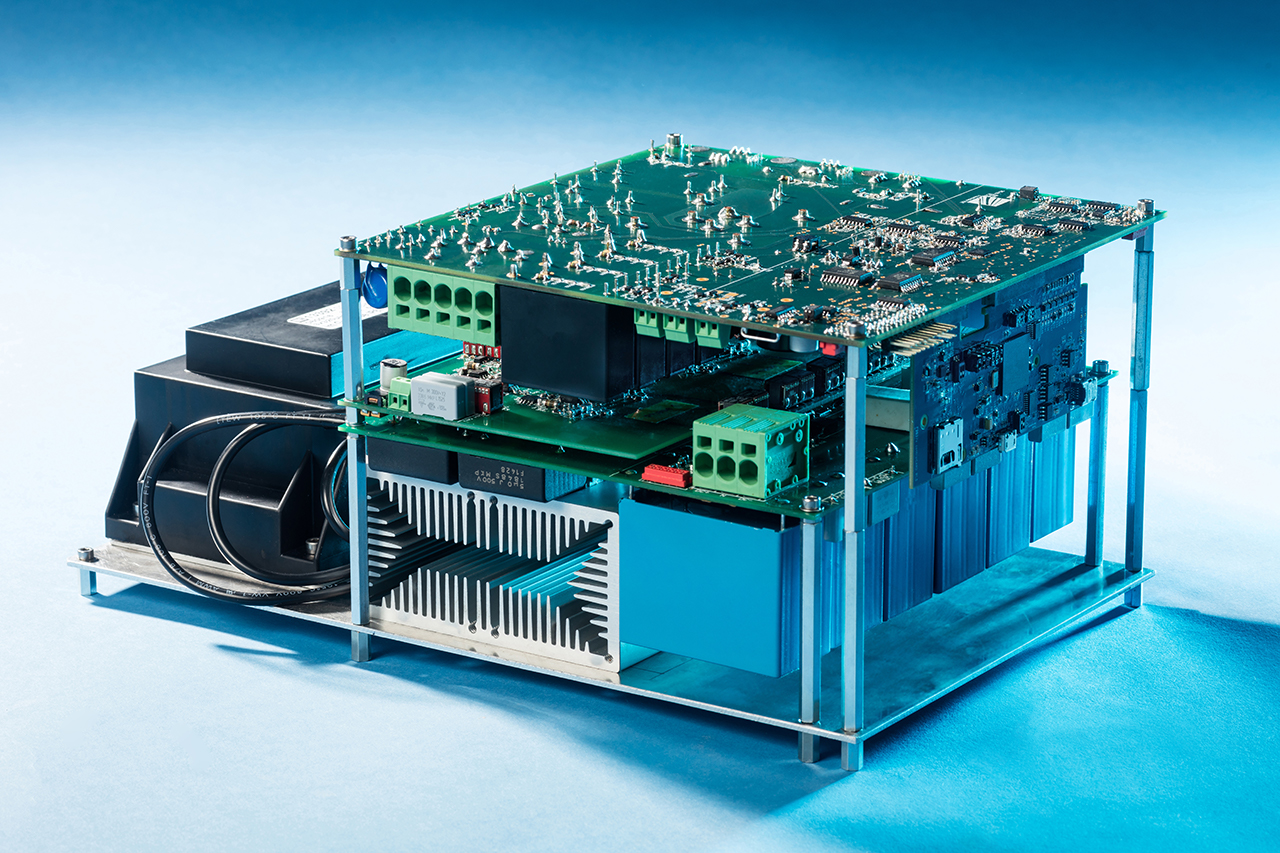

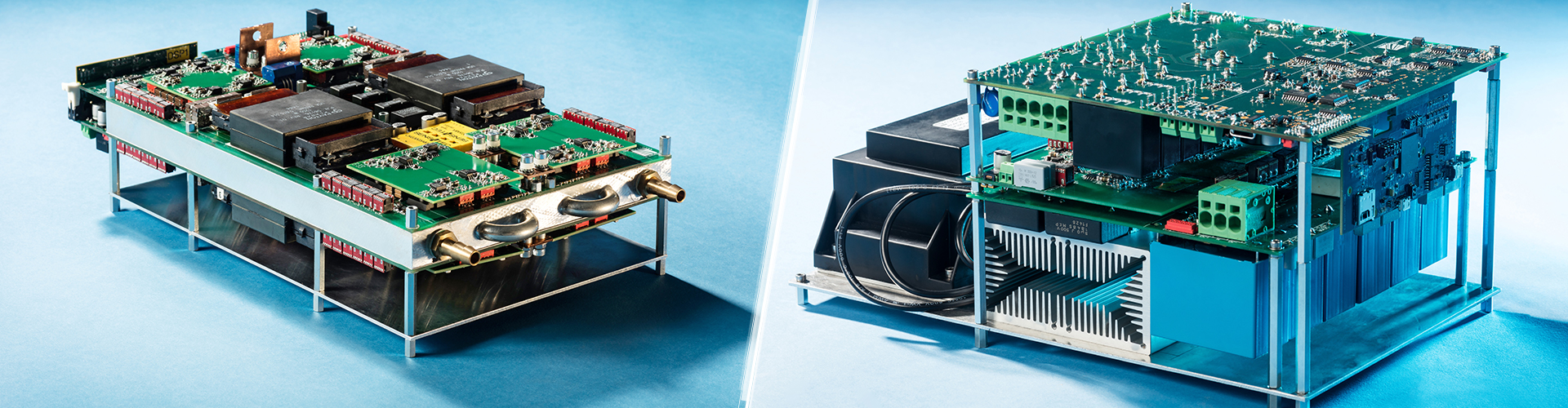

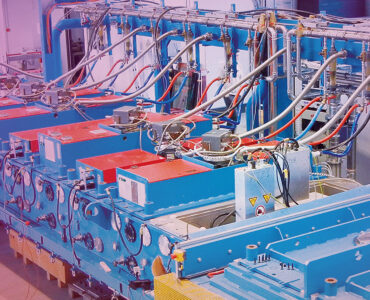

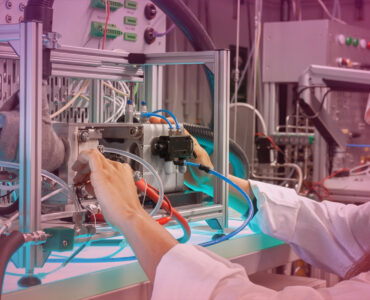

At Fraunhofer ISE, the research focus of the Department of Power Converter Systems is primarily highly efficient and compact power converters – components already used today in various commercial products. The research at ISE concentrates on increasing the efficiency in the partial load range. In addition, the newest semiconductor technologies like silicon carbide and gallium nitride are used with innovative topologies to increase the power density. Innovative designs as well as new cooling and connecting technologies are used to increase the compactness of power electronic devices.

Through our research activities in this field, we want to contribute to a wider and more effective use of stationary and mobile battery storage. This is indispensable for the success of the energy transformation and the integration of electric mobility in an intersectoral, renewable-based energy system.

By the way, we extrapolated the energy loss due to partial load operation based on our example of a PV system with home storage and an average inverter efficiency of 70%. Given the total number of home systems installed in Germany (ca. 60,000*), the energy loss was calculated to be 22.1 GWh. This is equivalent to the annual energy consumption of ca. 5500 households, based on an average annual energy consumption of a 4-person household (ca. 4 MWh/year) in Germany. **

*Source: Speichermonitoring Jahresbericht 2017, ISEA RWTH Aachen

** Calculation:

4300 h × (200 watt × (100 % / 70 % ) – 200 watt) × 60,000 = 22.1 GWh / 4 MWh = ~ 5,500 households

Congratulations for your designs. Silicon carbide is the way to go. I’m a proud owner of a fan less SiC based PC power supply and I never had any issues with it during years. SiC technology not only saves energy but also cooling effort, especially in air conditioned environments like server rooms. PV inverters in the desert can be ambient air cooled since SiC transistors have higher operating temperatures than their Si counterparts.