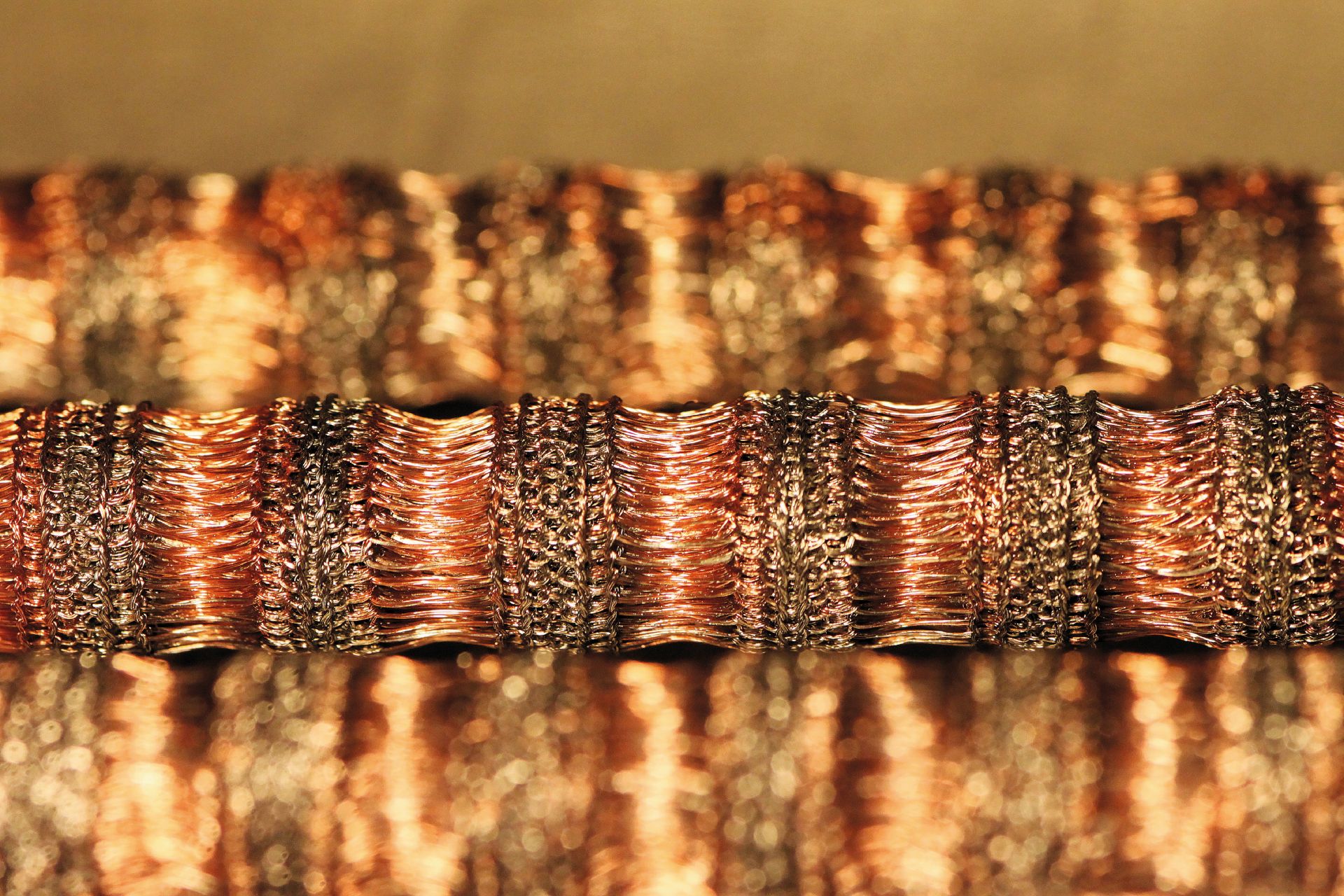

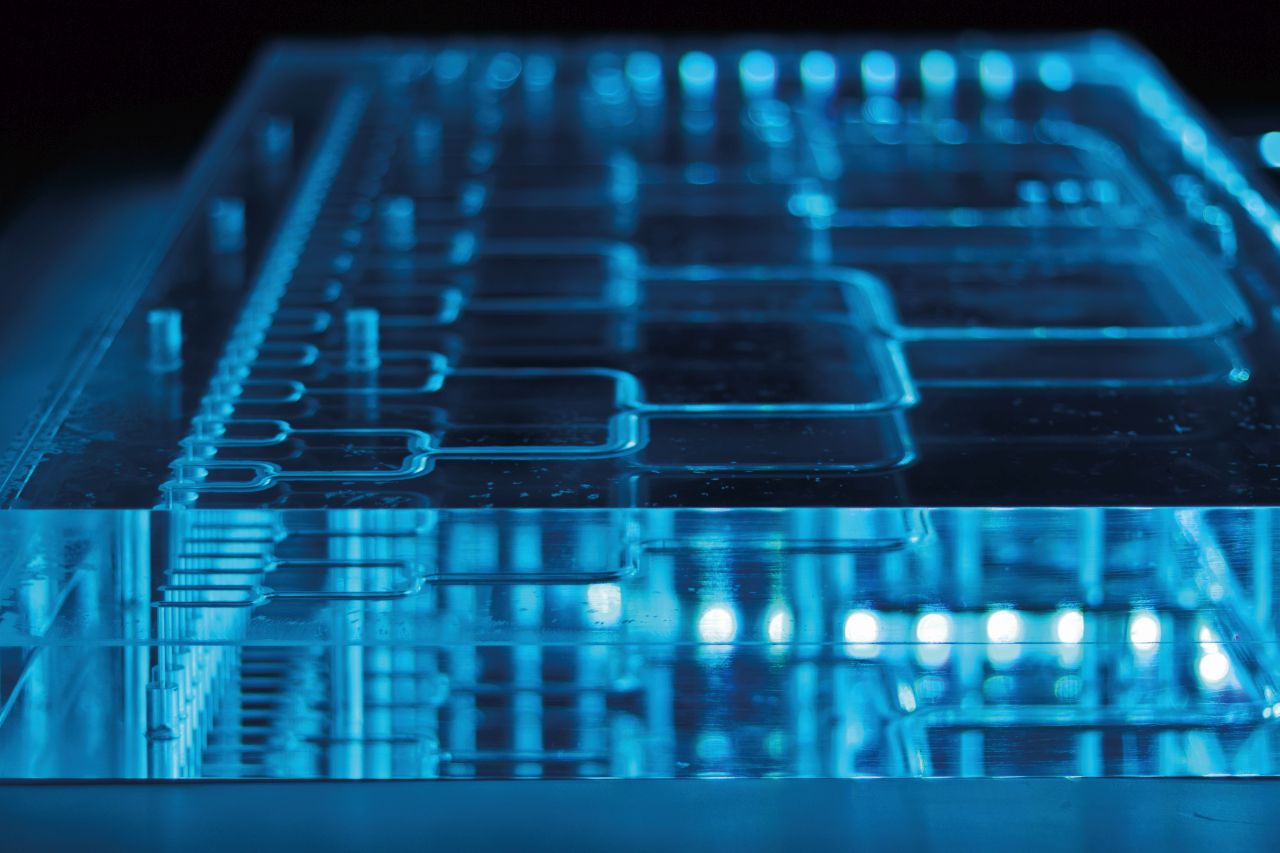

First of all, we hope the sparkling gold and blue stars on our card put you in a festive mood. Upon a second glance, you may have noticed the metal woven structure on the gold star and detected the vague pipe-like structures on the blue star. What is the significance of these structures and what does it have to do with winter?

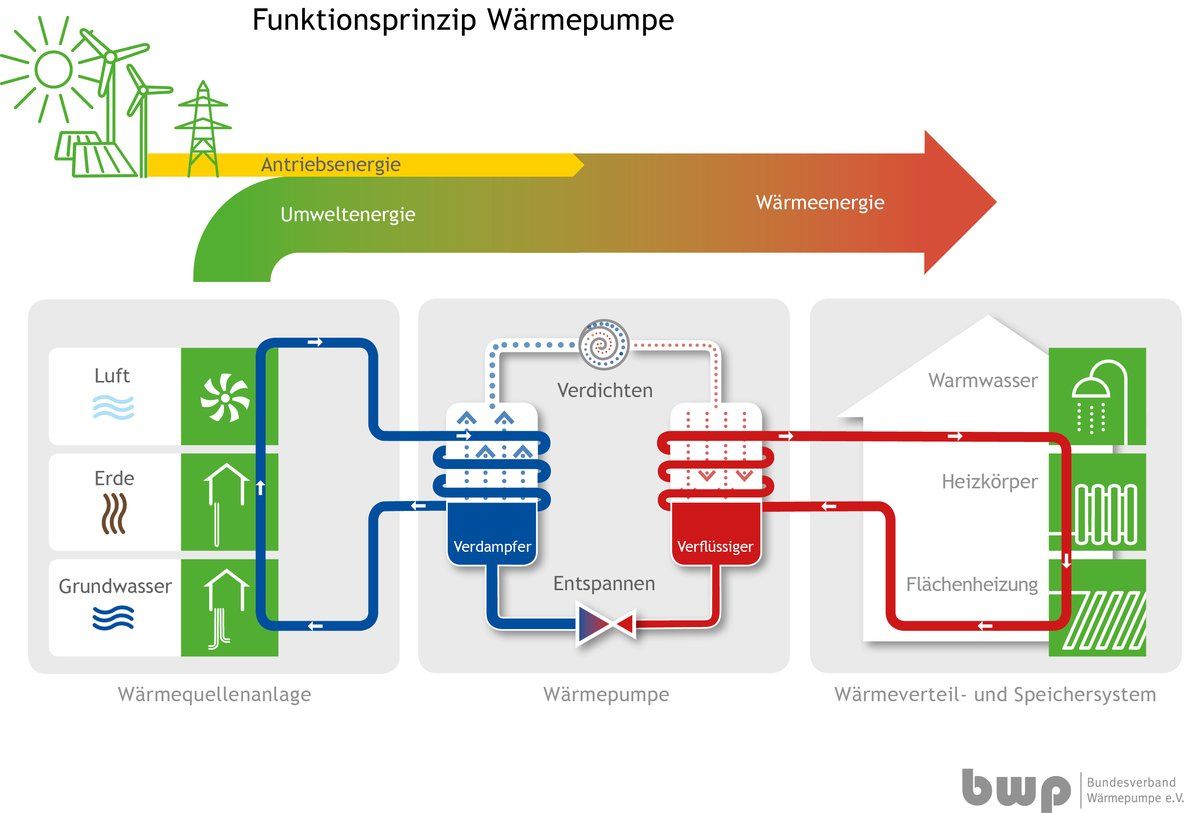

Both structures were developed at Fraunhofer ISE and are used in heat pumps. Heat pumps, a key technology for the energy system transformation, use environmental energy and electricity as driving energy to provide heat for buildings. Approximately 80 percent of the final energy in German households is used for space heating and hot water heating. Experts at Fraunhofer ISE estimate that heat pumps will supply between 65 and 90 percent of the low temperature heat in buildings in 2050, thus making them one of the most important heating technologies in Germany in the future.

Basically, a heat pump functions in a similar fashion to a refrigerator. In a heat pump, the heated, vaporized refrigerant is compressed, which raises its temperature and pressure. The hot refrigerant gas releases its heat into water and condenses. The warm water flows into underfloor heating systems, radiators or hot water storage tanks, while the liquid refrigerant, now cool, flows back into a so-called evaporator, where it once again absorbs heat energy. The cycle then starts again from the beginning.

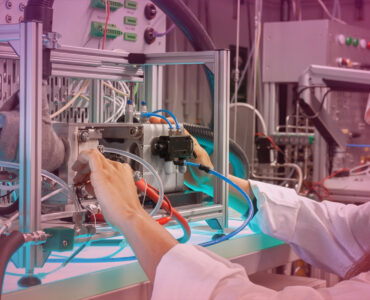

The structure seen on the gold star is actually a round copper pipe to which a sheath structure of woven and knitted copper wire has been soldered. The manufacturing technology for metal textile structures allows the enlarged surface area to be tailored to the specifications, e.g. oriented structures or zones of differing density. The illustrated structure developed at Fraunhofer ISE improves the sub-atmospheric evaporation of water, an environmentally friendly natural refrigerant in heat pumps. With this technology the volumetric specific energy could be tripled in comparison to conventional evaporators, and the energy consumption of adsorption heat pumps decreased.

The structure shadowed in the blue star shows a novel fluid distributor. In order that the refrigerant completely vaporizes or condenses, the vapor-liquid ratio must be identical in all of the channels. Generally, that’s not easy to achieve. A team from Fraunhofer ISE found their solution in nature. The bionic fluid distributor branches continually like a tree, achieving a uniform distribution of the refrigerant throughout all channels. Thus, the entire surface area of the heat exchanger is used efficiently and less refrigerant is required.

Both technologies help keep our living spaces warm in winter, and efficiently and sustainably at that!

Add comment