A novel system of optical elements redirects light so that the irradiance on the cells is increased, no light passes the pv module “unused” and more power is generated.

An important goal of PV module development is to convert as much light as possible into electrical power and to reduce losses from reflection and absorption. Since crystalline solar cells are limited in size, “inactive” module area is created in the spaces between the cells and between the cell strings which lowers module efficiency.

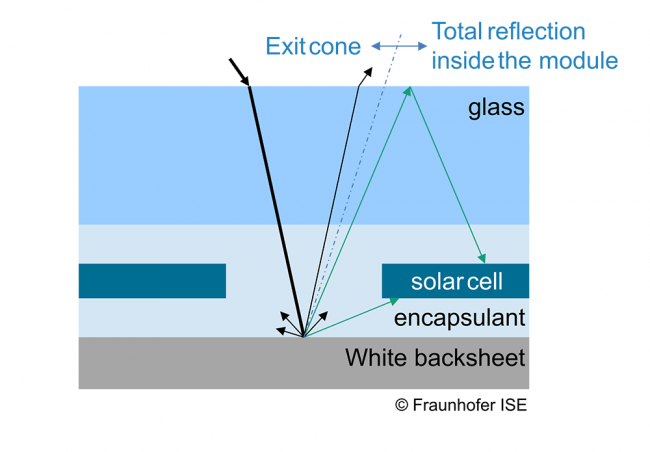

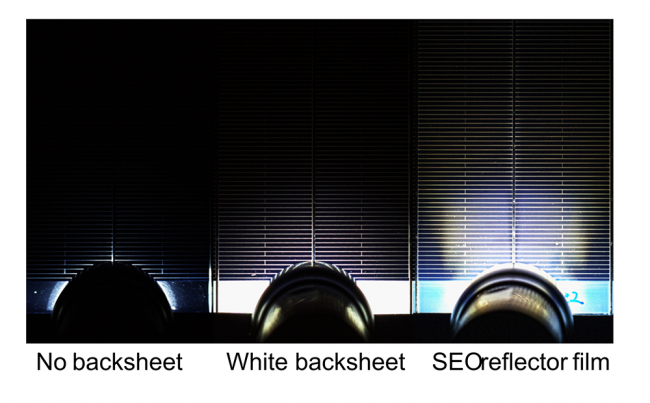

The PV industry is well aware of this loss and has been using white backsheets for decades now. These sheets reflect at least some of the light incident on these in-between spaces onto the cells. While the gains are significant (typically around 2% in power), the backsheet reflection which is mostly diffuse physically limits the amount of light that can be harvested from cell spacing areas.

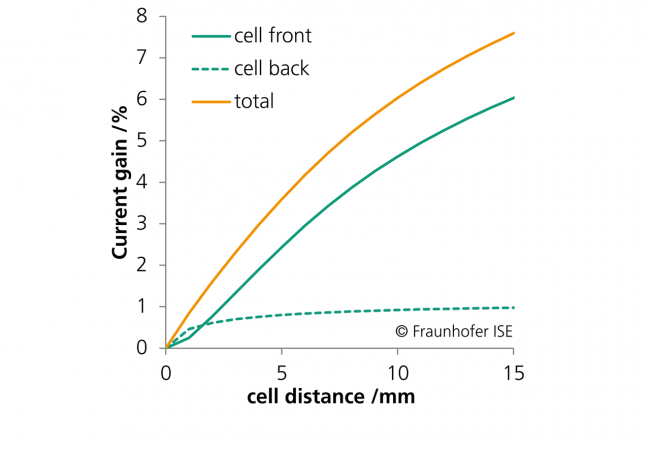

The diffuse reflection properties of white backsheets are also responsible for another phenomenon: The reflection gains increase with the inactive area. With more white area visible, more light is reflected onto the solar cell.

Using this effect is a relevant mechanism to increase the so-called “cell-to-module (CTM) ratio.” This performance indicator basically describes how much power a PV module generates in relation to the cells that are used. Of course it is easier to build a high-performance module with excellent solar cells but it is much more difficult to achieve a high module power with only mediocre cells – the CTM reflects that.

For a module manufacturer who wants to optimize module power, additional cell spacing might be an option. But losses in efficiency need to be considered, since the more inactive area that is added to the module, the lower the module efficiency will be. Since the solar cell is the most expensive component in a PV module, the use of reflection gains from cheaper components (i.e the white backsheet) is one method to lower the specific module costs (€/Wp).

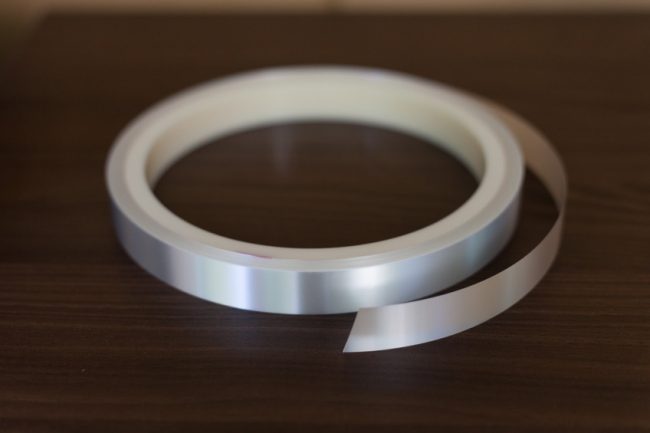

Efforts to improve the light management in PV modules therefore have a long tradition. Structured glass, reflectors on interconnector ribbons or anti-reflective coatings (ARC) are well known in the industry and many different approaches have been tried and commercialized. Interestingly, the white backsheet remained mostly just a white, diffuse reflector.

Some decades ago at the begin of the intense research on terrestrial photovoltaic modules, the first PV modules used a glass-glass setup with no backsheet. When cost pressure increased, the second glass was replaced with polymer films which added a benefit due to the reflection gains. A few years ago glass-glass setups were reintroduced for many reasons, bifaciality of solar cells being one of the most important.

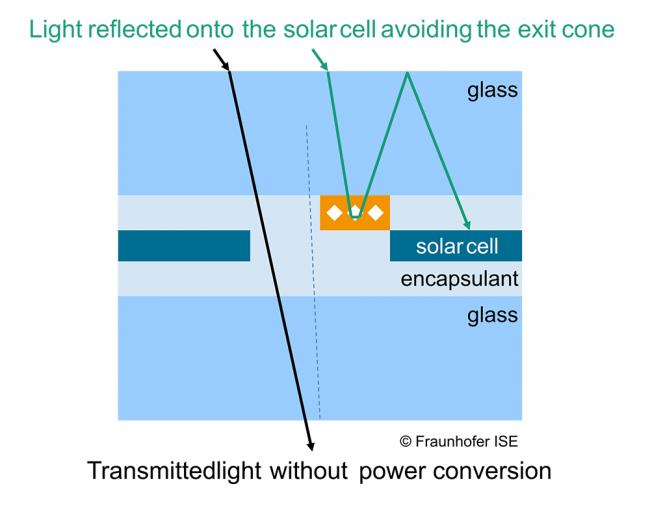

White backsheets are obviously not the perfect solution for bifaciality. Bifacial solar cells require a transparent rear cover in order to harvest the additional irradiance from ground reflection. On the other hand, glass is not perfect either, since the internal reflection gains are lost. A solution was required…

Intelligent Control System (ICS) and Fraunhofer ISE have now developed and tested a novel system of optical elements that profit from a directed reflection of light. The light is redirected so that the irradiance on the cells is increased, no light passes the module “unused” and more power is generated

Up to 10% gain in current has been measured at Fraunhofer ISE for cell spacings of 10 mm and about 6% for the more typical 4 mm-spacings.

The measurements at Fraunhofer ISE clearly prove that all module types can benefit from an optimized light management. The Solar Energy Optics (SEO) reflector can be used with backsheets. This technology is especially interesting for bifacial solar cells since it is applied only in the spacings between the cells and the cell strings and therefore does not shade the active rear side of the solar cells.

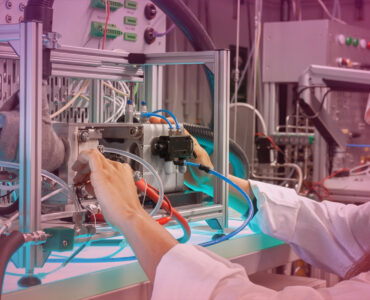

Fraunhofer ISE has tested the reflector for different module setups (e.g. glass-backsheet or glass-glass, full and half cells, mono and bifacial setups). Reliability tests are being performed at the Fraunhofer ISE TestLab PV Modules.

A very insightful and informative article, your work is much appreciated!