The basic principle of solar-thermal collectors is simple. All utilize sunlight to warm up a heat transfer medium and thereby make heat energy available. Some supply households in our latitudes with warm water and solar thermal heating. Other technological variants are located in the sun belt of the earth. Those feed power turbines with water steam and supply whole regions with electricity. Over the years, the technology has found new applications and the variety of solar-thermal products is enormous. Accredited testing institutions play a significant role to ensure the quality of solar collectors and other thermal heat generators, such as heat pumps, and to provide transparency on the international market. Dr. Korbinian Kramer, Head of the TestLab Solar Thermal Systems at Fraunhofer ISE in Freiburg, describes how a testing institution acts in such an environment and continues to reinvent itself.

No energy transition without heat transition. The numbers which have been cited for years confirm this fact: The desired CO2 reduction of 80-95 % until the year 2050 is only possible if the energy transition takes place in all energy sectors. Approximately 50 % of the end energy consumption in Germany and Europe are dedicated to the heat sector. However, the energy conversion in the heat sector is much more diverse than in the electricity sector. The reasons are decentralized, heterogeneous technologies, market and cost structures as well as a variety of stake holders involved. This is all the more reason to ensure transparency and comparability of the technologies and products – especially with the intended stronger coupling of the power and heat sector in the future. Making sure that the performance, reliability, and quality of different technologies is comparable, creates trust and the foundation for a targeted market development. This context is a central motivation for the work of our test laboratories in general and especially for the TestLab Solar Thermal Systems at Fraunhofer ISE.

More than 35 years of experience:

From the founding years to the energy transition

The basics of the TestLab Solar Thermal Systems have been in existence since Fraunhofer ISE was founded in 1981. Back then, it had a different name and was organized completely differently from today. But already the founding team of Fraunhofer ISE recognized the potential of solar-thermal technology for energy supply on the basis of renewable energies. In addition to research and development in this area, the aspect of testing was being developed. The laboratory has evolved over the decades and expanded its service spectrum. We have matured with the challenges of the market as well as those of our customers. Naturally, more and more complex questions regarding the development and quality assurance of solar collectors can be answered using computer added design programs. Manufacturers no longer have to build a prototype for every question which then runs through a testing cycle. But some tests can simply not be replaced by software programs and the complexity of the contexts between all testing factors can simply not yet be mapped by a computer. And that is why the TestLab Solar Thermal Systems continues to be among the most renowned accredited testing institutions for solar-thermal power worldwide and enjoys great appreciation in the international industry.

That still does not constitute a reason to rest on our laurels but for us, the motto remains: “Stay on track”! Because the market for solar-thermal collectors has become increasingly global and each national market is undergoing a different developmental stage. Highly automated manufacturing on a large scale is being operated while niche markets are being served by small, highly specialized crafts persons. Furthermore, additional technologies and products for heat generation have been launched. That is why we no longer restrict our service offer to solar collectors, which we test under natural and simulated weather conditions, temperatures, and loads, but we also test water storage systems, pumps, or valves. Not a year has passed during which we did not develop new tests for new challenges or innovative products. Recently, we have transferred our experience especially to our service offer for testing heat pumps. In addition to many technological analogies for detailed questions, we also provide the advantage of applying the Keymark quality label for heat pumps starting in 2017 – the same certification system which we have been using for ten years for solar-thermal technology.

Service beyond the standard:

The winter test for solar collectors

The European Norm (EN) 12975 or EN ISO 9806, respectively is applicable for the tests of solar-thermal collectors. It also specifies the required mechanical testing processes, for example. In this context, the TestLab Solar Thermal Systems tests the performance and function of solar collectors and carries out tests along with the development for eventual approval of new products. For traditional collector tests, customers especially look for speed and reliability. Nonetheless, the bandwidth can be quite large, depending on the type and scope of testing. The most simple tests of standard collectors can be wrapped up in 2-3 days while complex testing processes can take up to 9 months. The laboratory also develops new testing processes and equipment to enable special testing beyond traditional framework conditions. Not least because we at the TestLab Solar Thermal Systems frequently gain insight into new developments at an early stage where we can determine where the testing norms are ready to handle the innovative products or whether adjustments are needed. This reflected and proactive process is a central aspect distinguishing our situation from the one of other testing institutions.

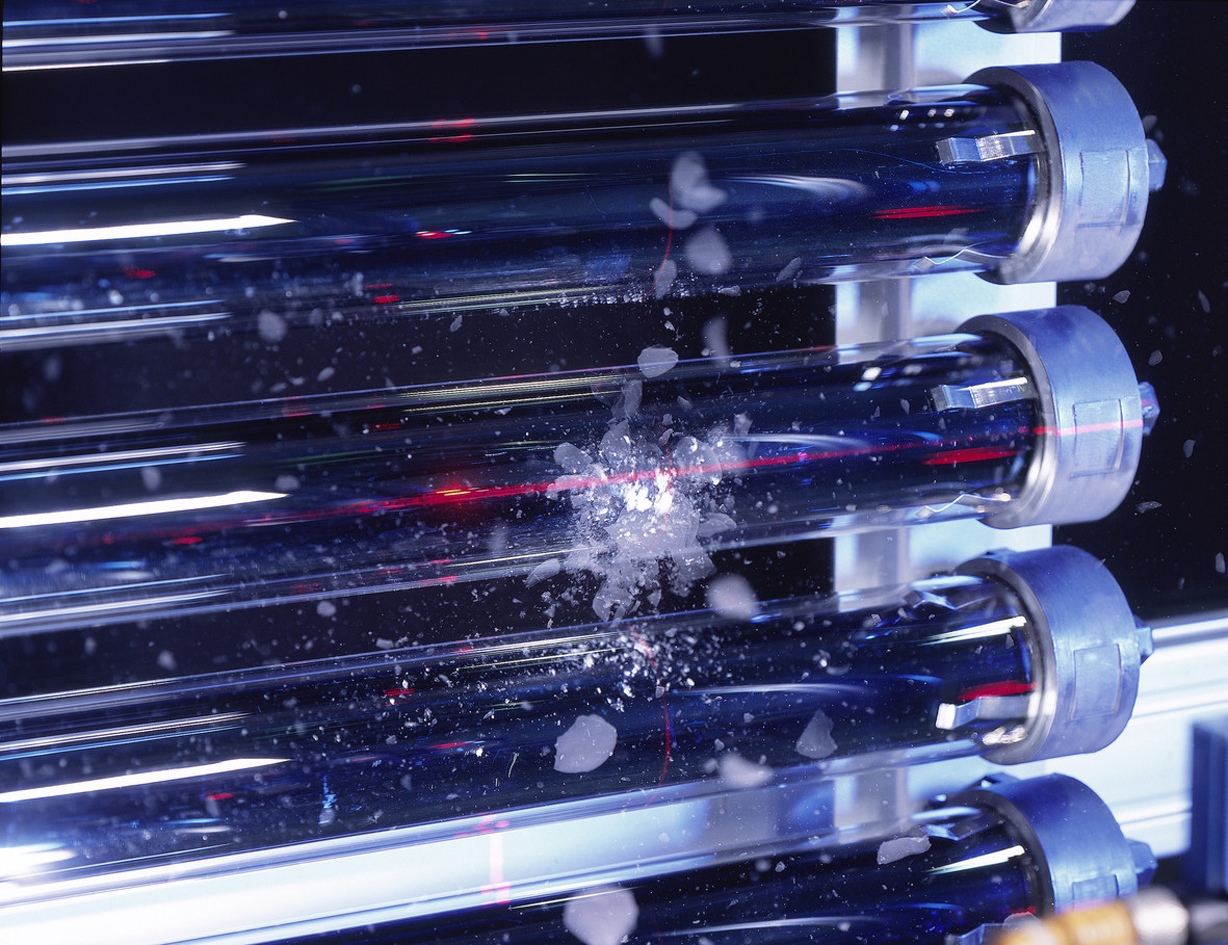

For example: We developed and use testing equipment which can simulate realistic snow and wind loads. Of course, it is not relevant for all collector types and target countries but it is crucial for some. Our goal was to have the solar collectors undergo an indoor test to determine the realistic limits of the mechanical load capacity of collectors. Flat plate and evacuated tubular collectors up to nine square meters in size can be tested, also because computation processes are not necessarily able to do so. To test these limits, the specimen (PV modules or solar collectors) are subjected to up to ten tons of pressure and tension. The special feature of the test rig is the fact that loading tests can be carried out at temperatures ranging from -40 °C to +60 °C. We can also simulate cyclical and asymmetrical loads as they occur in reality due to snow and ice piling up (ice damming). The test rig also enables testing of mounting equipment and assembly systems of collectors at different temperatures and realistic load situations. These factors are crucial, especially for organic material components, such as adhesives or polymer-based connectors, and are not being considered by the standard.

Interplay of the industry:

Competition and transparency are not mutually exclusive

By developing such test rigs, we not only serve a need of our customers and expand our portfolio but also generate important knowledge as input for future testing standards and feed those back to the corresponding bodies. This interplay – and the common motivation as well, despite all the competition – in the solar-thermal industry in our opinion significantly contributes to ensuring progress, quality, and transparency on the market. We were able to make positive contributions to this area of potential conflict over the last years with our experiences and our network, and we support positive market development. In addition, we not only carry out testing ourselves but also advise investors and operators in constructing their own testing equipment. Ostensibly, that may result in more competition but we can support the adherence to international standards and comparability of products worldwide by looking a bit further.

And the TestLab Solar Thermal Systems provides another advantage when it comes to shaping the situation for industry and implementing the heat transition. As a research institute, Fraunhofer ISE operates applied research in the area of solar-thermal energy and many associated disciplines in addition to the test rig. As an accredited testing laboratory, we provide a neutral baseline study with our final report but we do not make any recommendations for the optimization of products. However, independent projects can be started with our colleagues in the scientific development divisions to research and realize possible optimization potential. This may be a significant advantage for customers who may require support in the development of their products. My team also profits from the know-how of the institute and from short paths to specialist colleagues, for example experts on coating, when it comes to advancing our own methods and processes.

Experience and consulting:

The greatest equipment is no guarantee for success

Our TestLab Solar Thermal Systems is equipped in accordance with the requirements of international standards and beyond. Its infrastructure fulfils the conditions for tests as per Solar Keymark, Solar Rating & Certification Corporation (SRCC), and Energy Label. That is most certainly a basic prerequisite for success but not a guarantee. The most important factors are the experts working with such equipment. Our employees come from the engineering sector as well as from science. Many of them had previously completed practical training and have been with us for a long time. Together, we have gauged and assessed many more than 500 collectors and systems for our customers. That is a treasure of experiences which we can access for every new customer request.

One of our strengths is our individual consulting service before the actual testing takes place. The more we find out beforehand by listening and asking the right questions, the more targeted and cost effective our offers can be. For most of our customers, the know-how and high-quality consulting are essential and help build a trustful relationship. As a team, we used to enjoy even more freedom in the times of 40 % market growth for solar-thermal collectors. But we continue to enjoy trying out new things, tinkering with new concepts, and we see our work validated when one of our suggestions is actually implemented in a revision of a standard. For example, we managed to have all German manufacturers of air heater solar collectors gathering at one table and to join forces to develop an industrial standard to serve as a basis for marketing products in competition to one another. This process took a lot from all parties of interest involved but in the end, transparency and acceptance of new technology was significantly increased.

| The TestLab Solar Thermal Systems tests solar-thermal components and complete systems. The test center is recognized by DIN CERTCO and fully accredited by the German Accreditation Body (DAkkS). In addition, the TestLab Solar Thermal Systems supports customers in developing their products. A large outdoor weathering area as well as laboratories equipped with the most recent technology are available for service worldwide. Furthermore, the TestLab Solar Thermal Systems also actively participates in the development of new testing methods for standards as well as individual questions. |

Add comment