What is the ideal operating temperature for electric cars? At what temperature do they perform best? The participants of the European research project JOSPEL are addressing just these questions by assessing the optimization potential of electric vehicles. The project aim is to increase the energy efficiency and range of electric vehicles by applying efficient and cost-effective climate control solutions especially developed for battery electric vehicles. Experts at Fraunhofer ISE are working with industry partners on optimizing battery operation, with the goal of increasing battery lifetime through improved thermal management.

Battery Electric Vehicles – Major Potentials, Major Obstacles

Today there is much discussion about transforming the transportation system and thus battery electric vehicles (BEV), i.e. electric cars, buses and the like. Environmental pollution due to traffic in urban areas is becoming increasingly evident. This is supported by air pollution measurements that show the upper boundaries set down by law are often exceeded. The diesel scandal and the public debate about implementing restrictions on driving are examples of the problems facing today’s transportation system.

Electric vehicles can help solve this problem, yet they are only slowly finding their way onto the streets. Hesitation still exists, although various types of electric autos are available that have long been proven fit for daily use. Reasons for this are the high cost of purchase, some uncertainty about the future development as well as a shorter range, which is especially critical due to the longer charging times.

The JOSPEL Project

The JOSPEL-project’s aim is to increase the energy efficiency and range of electric vehicles by applying efficient and cost-effective climate control solutions especially developed for battery electric vehicles. By climate conditioning, one thinks immediately of the passenger compartment, however, it also is relevant for the optimized thermal management of the car battery. Fraunhofer ISE is working on this particular aspect together with partners from industry.

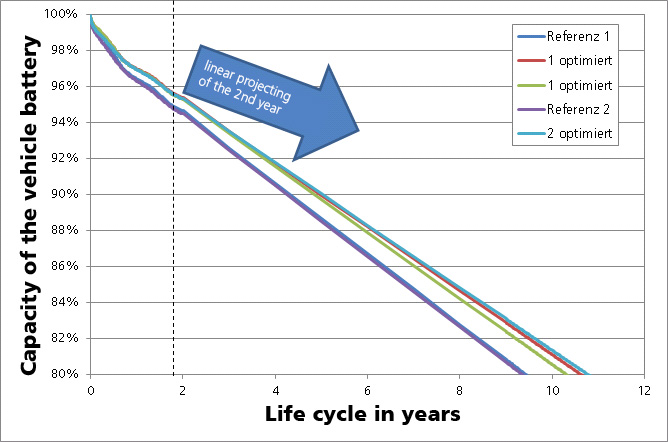

The goal of the working package under the leadership of Fraunhofer ISE is to increase the battery lifetime by at least 15 percent and at the same time reduce the energy needed for battery cell temperature control by 12 percent. The name “JOSPEL” stems from a combination of the Joule and Peltier effects that serve as the basis for the technologies developed.

The Simulation Model: Searching for the Optimal Temperature

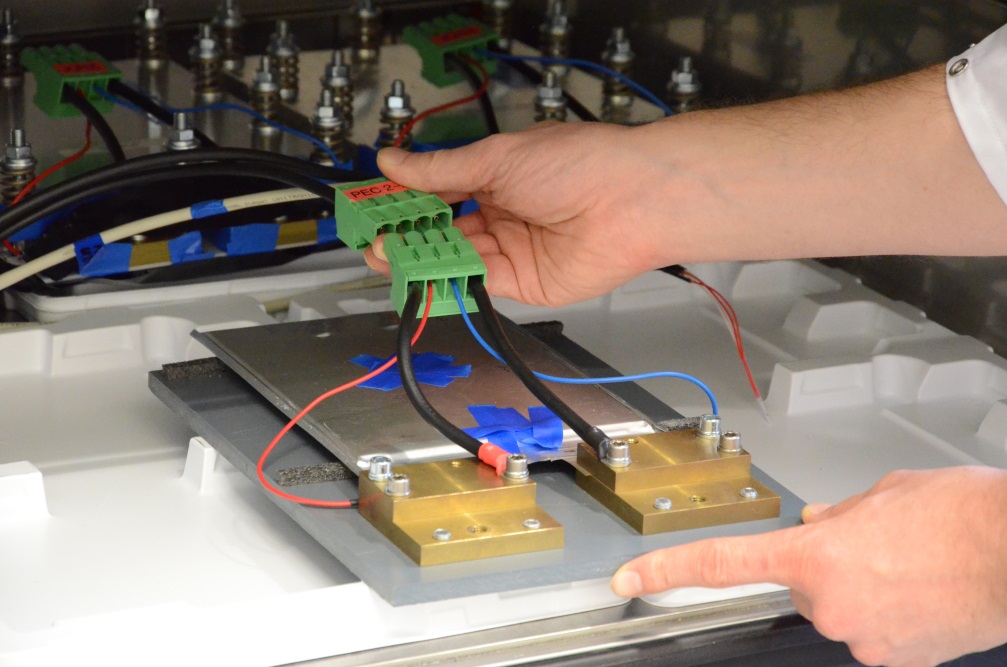

At the beginning of the project, we informed our partners about the available lithium ion battery cells and their most important characteristics. Then, a suitable battery cell was selected for the project using a tool, developed at Fraunhofer ISE, to carry out a cost-benefit analysis. The chosen cell was then measured in detail in the Center for Energy Storage Technologies and Systems. Using the measurement results, we developed simulation models to determine the electric and thermal behavior and the course of aging. These were verified by performing additional measurements.

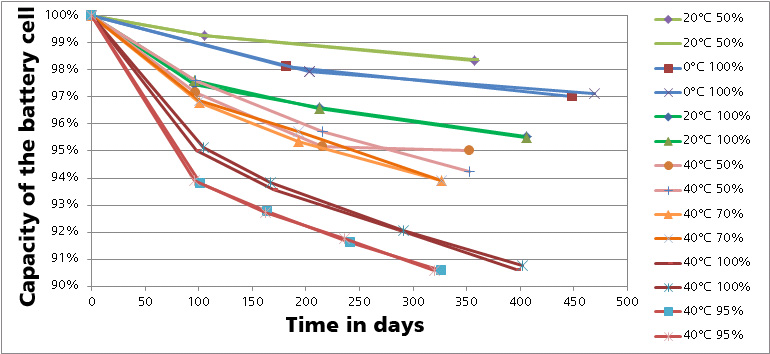

Based on these models, we developed a simulation to determine the effect of different parameters on the efficiency and battery aging. The parameters considered included various operating parameters, cooling and heating scenarios and operating strategies.

Measure the Success: Increases in Efficiency and Lifetime

Using development tools, we can not only determine the ideal temperature range for the chosen battery but also define various beneficial operating strategies. One example looks at preconditioning the temperature of the battery system before start. The simulations showed that it is better to heat up a cold battery system before starting to drive.

Although additional energy is required to heat the battery, a warmer battery provides more energy, that is, it runs more efficiently at higher temperatures. The higher energy efficiency on the other hand positively influences the range and aging. In all, these aspects justify the additional energy expenditure. With the simulation tools of Fraunhofer ISE, such synergy effects can now be identified for special applications and also be proven with hard numbers.

The project is currently in the final third of the project duration. In this phase two demonstrators are to be built in order to test the functionality and advantages in the field.

Further Information…

We use YouTube in order to embed videos. YouTube uses cookies in order to collect information about the visitors of its website. Starting the video might initiate data processing operations. The Privacy Policy of YouTube provides further information on this.

Further videos of the project partners

Research Topic »Battery Systems for Stationary and Mobile Applications«

Add comment