A newly developed solar thermal venetian blind uses the heat generated by solar radiation and feeds it via heat pipes to the hot water storage tank of the building. …

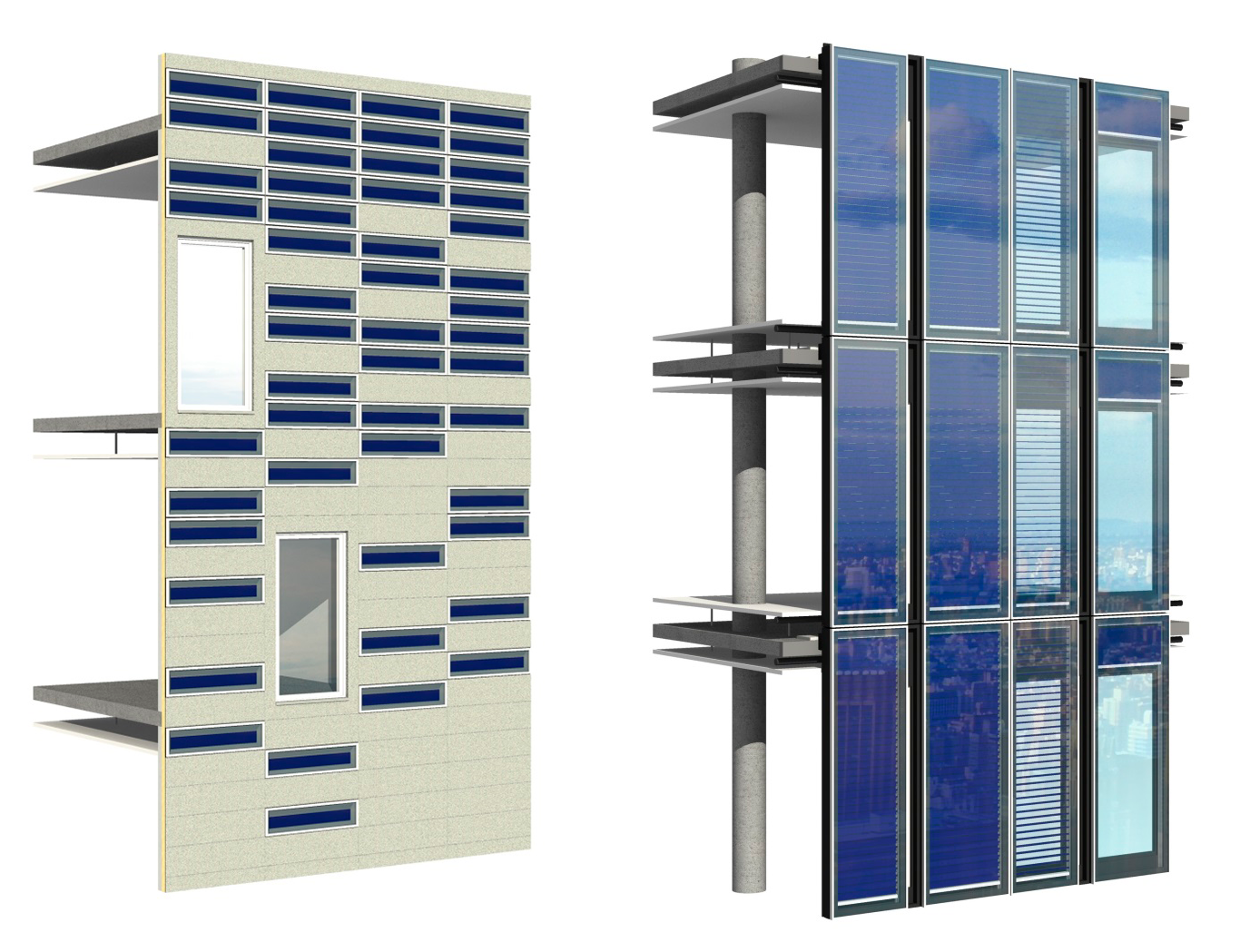

When you think of solar thermal energy, you think of “black rectangles on the roof”. To date, this has been one barrier to the widespread use of this technology because potential customers have been bothered by the appearance of the collectors. For this reason, the project ‘Arkol’ is developing two new types of façade collectors: a strip collector for the esthetically flexible design of opaque surfaces of the building envelope and a solar thermal venetian blind for the transparent surfaces (Fig. 1). The venetian blind has the full mobility of a normal blind. There is just one additional function – the heat dissipation from the slats.

The esthetics of skyscrapers in large cities have a broad impact, although they often consume a great deal of energy. In many cases, blinds are used between glass panes, which can reach temperatures of up to 100°C due to solar radiation. The solar thermal venetian blind uses this excess heat and supplies it to the building’s hot water storage tank via heat pipes built into the slats. This also reduces the temperature of the surface on the room side and the cooling demand of the building. As a multifunctional façade element, the solar thermal venetian blind not only ensures a pleasant room climate and good glare protection, but also reduces the energy demand of the building, e.g. for hot water or air conditioning.

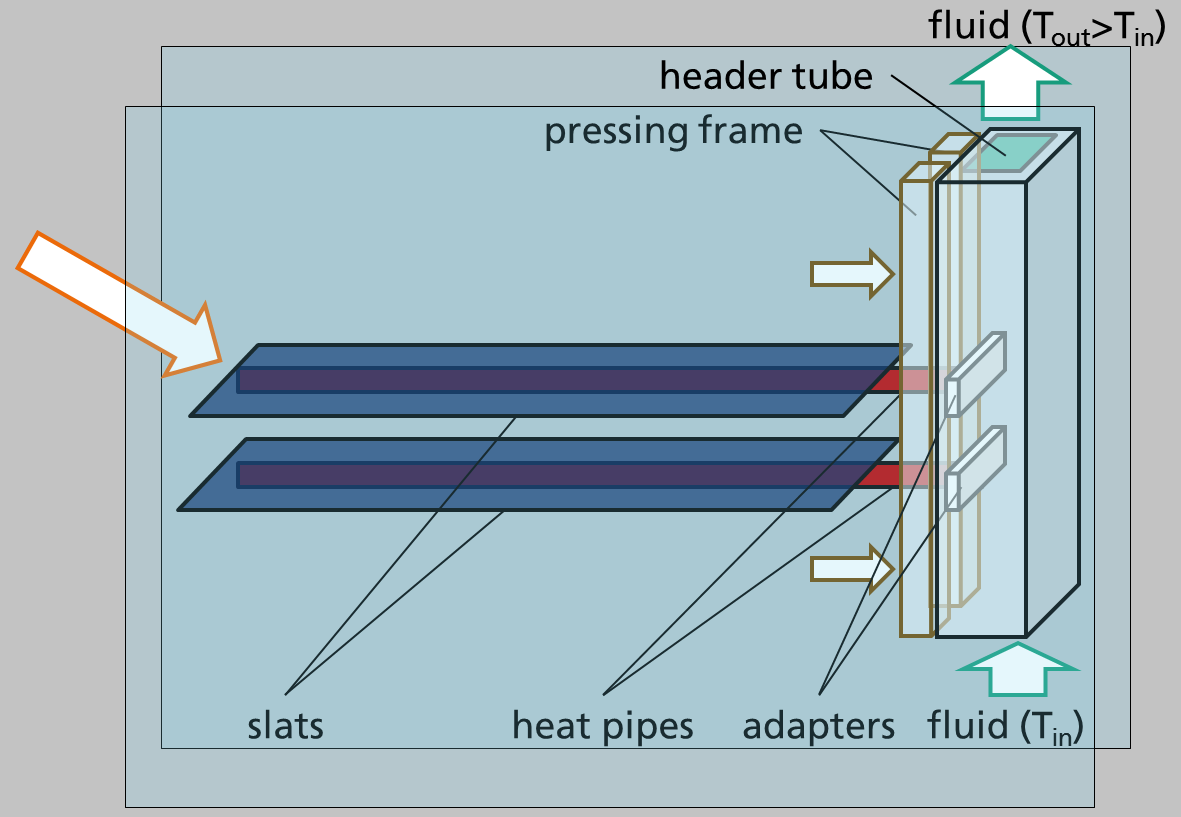

A switchable thermal coupling has been developed to transport the heat from the movable slats into the stationary collecting pipes. An aluminum adapter, which is connected to the heat pipe, is pressed against the collecting duct (a heat exchanger laid vertically in the façade) by means of compression springs. If the position of the slats has to be adjusted, the press contact is released and the venetian blind is as mobile as any other blind. In the first laboratory test sample, which has been manufactured and assembled at Fraunhofer ISE in recent months, the thermal coupling is opened with the aid of lifting magnets. Depending on the design, a pressure mechanism via a camshaft can also be used.

The dry connection of the thermal elements not only guarantees the necessary mobility and good heat conduction, but also offers advantages in terms of installation, maintenance and operational safety.

New concepts have also been developed for the use of heat pipes in horizontally aligned slats. For example, experiments have been carried out with different levels of the working medium with regard to optimum efficiency.

Finally yet importantly, all components must be designed in such a way that they function as maintenance-free as possible over a period of 30 years, despite the potentially high temperatures inside the double façade.

Innovative and yet competitive

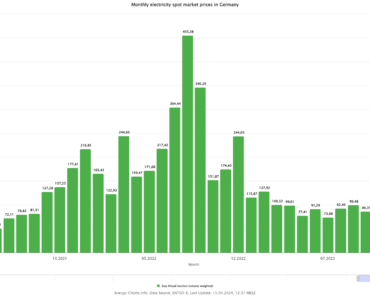

According to initial estimates, the solar thermal venetian blind will also score well in the costs category (compared to retrofitted solar thermal collectors). It is manufactured from mass-produced parts and places little additional demands on façade constructors, fitters and installers. The installation of venetian blinds in closed cavity façades is already common practice; therefore, the additional effort is low. In view of the service life of a façade, it will probably be even more economical to use solar thermal venetian blinds than only conventional blinds. Nevertheless, there is the initial attempt that solar thermal venetian blinds are being used in prestigious high-rise projects that radiate into the architecture of everyday life and that open up the market for the mass production of solar thermal venetian blinds due to the large areas.

The next step will be thermal measurements on the test bench on the laboratory test sample. The main aim is to measure the yields at different angles of attack of the slats in relation to the position of the sun. The results are used to create a simulation model of the solar thermal venetian blind. This will be used to quickly compare different variants in a construction project on the computer.

In October 2018 and January 2019, the laboratory test sample will be presented to the public for the first time at the trade fairs Glasstec and BAU.

We use YouTube in order to embed videos. YouTube uses cookies in order to collect information about the visitors of its website. Starting the video might initiate data processing operations. The Privacy Policy of YouTube provides further information on this.

This is a fantastic and commendable innovation. As a follower of renewable energy and integrator, I am looking at the UK and African market. I believe this will be perfect for luxurious high rise projects in Nigeria, which is the only construction type I am focusing on this lucrative market. I will like to address the issue of cooling alternative instead of the carbon polluting and energy guzzling air conditioning systems in Africa.

Thanks

Best Regards

Ola Bello

Bospec Projects International Limited

+44 7955281011

Kindl