Episode 5 of a series on heat pumps in existing buildings

Heating systems with heat pumps are usually equipped with a direct-electric back-up heater. Usually, the electric back-up heater takes over the heat supply from a defined outdoor temperature (for example, -5°C, also called the “bilvalence point”) – either alone or together with the heat pump. This can limit the required size (power) of outside air heat pumps.

On the one hand, this smaller size improves the economy of the system, and on the other hand, it optimizes the efficiency of the heat pumps at higher outdoor temperatures. If the discrepancy between the heating load (heat demand) of the building and the capacity of the heat pump is to large, the compressor (of the heat pump) operates more than required. This can reduce its service life span. With capacity-controlled heat pumps, which can adjust their capacity according to the prevailing conditions, this happens much less frequently.

In comparison to the heat pump, the efficiency of the back-up heater is much worse. The basic assumption is that electric heaters convert one unit of electrical energy into one unit of heat. In contrast, most heat pumps provide between 3 and 4 units of heat per unit of electrical energy (see previous episode of series). Thus, they are 3 to 4 times more efficient than back-up heaters.

How often do back-up heaters need to operate?

If the back-up heater of a heat pump system is used frequently, this is therefore bad for both operating costs and ecology. There is often a prejudice against heat pumps that the back-up heater must be used frequently and that heating costs will “explode” as a result. Field studies clearly disprove this assumption.

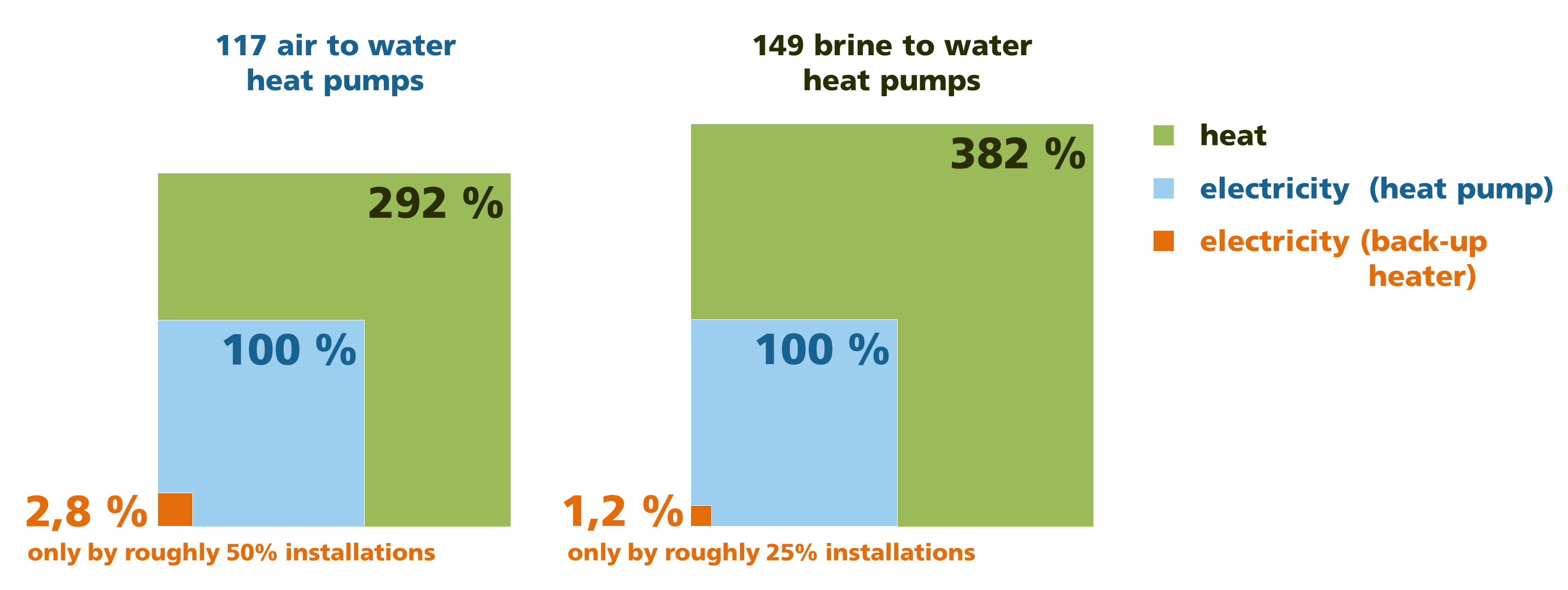

The graph represents a cross-evaluation of a total of 266 heat pump systems monitored in the field. The 117 air-to-water and 149 brine-to-water heat pumps were investigated within a framework of 4 research projects (two each in new and existing buildings) in the last 15 years.

From 100% electrical energy (blue area) the outside air heat pumps provided 292% thermal energy, the ground source heat pumps (green area) supplied 382%. This corresponds to efficiency values of 2.9 and 3.8, respectively. The orange area represents the electricity consumption of the back-up heaters. For the air-to-water heat pumps, the share of electrical energy required by back-up heaterswas only 2.8%. It should be noted that in about half of the installations, the back-up heaters had not worked at all (regardless of whether in new or old buildings).

In the last monitoring project covering heat pumps in existing (older) buildings, the relative back-up heater work in air-to-water heat pumps averaged only 1.9%. Significant operation of the back-up heater was only observed in cases of incorrect settings, defects or as a result of legionella protection during water heating.

Back-up heater operation was significantly lower for ground-source heat pumps than for outside air heat pumps, averaging only 1.2%. In about 75% of the systems, no work of the heating rod was detected at all. The practitioner is not surprised by these values: in the case of ground-source systems, the back-up heater serves only as a backup in the event of a defect.

What costs can you expect from a running back-up heater?

Thus, the back-up heater are rarely used. But what costs can be expected? This depends on several factors. A house with 150 m² of heating surface, a heat pump with an efficiency of 3.0 and an electricity price of 25 €-cents per kWh were taken as a basis for the following calculations. Assuming that the back-up heater share is 1%, the annual cost of the back-up heater for an unrefurbished old building (heating energy demand of 150 kWh per m² per year) is 37.5 € For a new building (heating energy demand of 50 kWh per m² and year) they amount to 12.5 €!

Theory and practice show unanimously that the back-up heater shares in the operation of correctly planned and designed heat pump systems do not exceed 3%. A larger share indicates in most cases optimization potential in the heat pump system. Thus, the use of the back-up heater has no relevant effect on the efficiency of the heat pump system.

The previous episodes of the series have mainly dealt with basic correlations and averages from field studies on a variety of real heat pump installations. In the next episode, we will present two cases of heat pumps in existing buildings in greater detail.

Further reading:

Overview on the range of applications for heat pumps.

Episode 3 of this series: Does a house have to be renovated first in order to install a heat pump?

Episode 4 of this series: How well do heat pumps really work in existing buildings?

Header picture:

House in Sachsen, Germany using a brine-to-water heat pump, © Bundesverband Wärmepumpe (BWP) e.V. More information on the project (In German)

This blog post is financially supported by the Climate Neutrality Foundation.

Add comment